EASYBUILD FACTORY

Build a prefabricated factory by EASYBUILD products. Industrial factory construction with high quality steel structure, strong, durable, according to engineering standards.

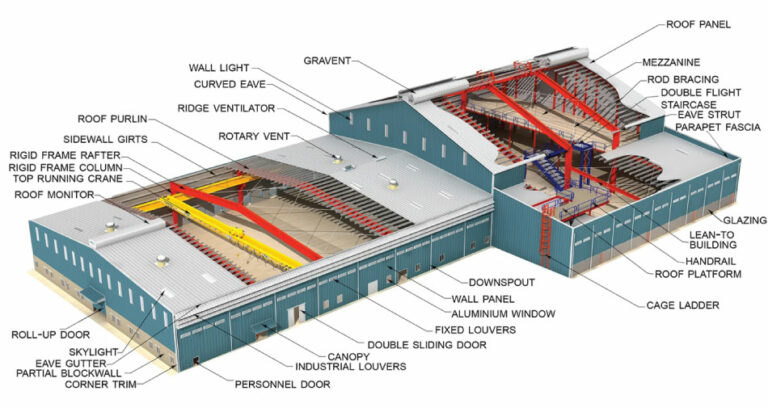

Ready-made factory EASYBUILD Construction of industrial buildings with high-quality steel structures, strong, durable, according to engineering standards and can also support the addition of the mezzanine or additional to the second floor of the building as needed. Customers can also install Overhead. Crane according to the size required by the customer, including the installation of ventilation fans or various machinery equipment that the customer needs in the factory building, can be installed according to the use of the customer.

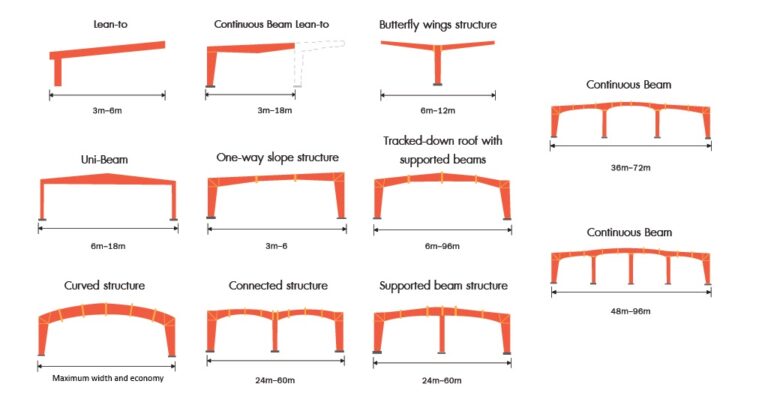

EASYBUILD prefabricated factory buildings can also be designed to support the use of general factory buildings, either single-storey or more than one floor, and in the form of a special factory building for specific use or the need for a factory building to have a height of Factory buildings at a higher level than normal, which are prefabricated factory buildings, EASYBUILD is able to construct buildings to meet the needs of customers.

Advantages of prefabricated factory buildings EASYBUILD

EASYBUILD It is outstanding not only the appearance but also the design to suit your business due to the EASYBUILD prefabricated steel structure. It can be made in many forms, it is also engineered to provide durability and strength.

Advantages of prefabricated factory buildings EASYBUILD

EASYBUILD It is outstanding not only the appearance but also the design to suit your business due to the EASYBUILD prefabricated steel structure. It can be made in many forms, it is also engineered to provide durability and strength.

Prefabricated factories are suitable for large structures.

EASYBUILD prefabricated factory designs steel structures with a width of up to 100 meters (ClearSpan) without pillars in the middle of the building. The distance between the side columns is up to 10 meters wide and the height of the prefabricated factory walls from 3 to 30 meters.

The finished factory supports the installation of Overhead Crane.

EASYBUILD prefabricated factories are designed to support the installation of overhead cranes according to the size required by the customer and support the installation of monitors. ventilation fan and various machinery equipment

Prefabricated factories design their buildings according to their practicality.

EASYBUILD prefabricated factories can be used in a variety of applications and the building can be designed to suit the application for your business.

The finished factory meets engineering standards.

All parts of the EASYBUILD prefabricated factory are designed and certified according to engineering principles with construction standards.

Prefabricated factories can be constructed more than 1 storey.

Prefabricated Factory EASYBUILD is designed to support the use of a prefabricated factory either as a single storey or more than one storey and can also be designed to have the height of the prefabricated factory according to the actual use.

The finished factory is strong and durable. have standard

It is strong, durable, has standard quality, is confident in the assembly of our buildings. Since the EASYBUILD pre-fabricated spiral salad is constructed of high-strength steel, the building’s tightness is guaranteed even in highly variable environments.

The finished plant has a long service life.

The finished plant can save costs, have a long service life. There are 2 coats of anti-rust paint and coating on the face, and the female nuts, male nuts and washers are coated with another layer of zinc. thus ensuring that the finished factory EASYBUILD Good abrasion resistance

Prefabricated factories can save construction time.

Ready-made factory EASYBUILD assembles the building with Knock system. Down. All parts are produced from the factory. No welding during installation, saving construction time 50% more.

Ready-made factory with after-sales guarantee

EASYBUILD prefabricated factories have a guarantee for various works, including a 10-year guarantee on the design of the prefabricated factory structure, a 1-year warranty on the installation of the prefabricated factory structure, and the standard BlueScope Lysaght metal sheet wall and roof warranty.

EASYBUILD prefab factory building example

iyaravanich Company Limited has earned the trust of many leading business owners in the country with impressive services in the design, manufacture and installation of prefabricated systems, which are examples of prefabricated factory construction. EASYBUILD

NW Factory

The size of the prefabricated factory is 1,000 square meters. The main structure of this prefabricated factory Able to support the installation of a 5 ton crane, the building floor supports the weight of 2,3 tons/square meter.

Prolog Titanium

Prefabricated factory size 900 square meters, height 10 meters. The main structure of the prefabricated factory EASYBUILD supports a crane of 20 tons.

S.A.S. INTERPLASTIC FACTORY & WAREHOUSE

The size of the prefabricated factory is 2,740 square meters. The factory building is divided into 3 parts for the internal use of the building: offices, assembly zones, and warehouse.

Sutthipong Concrete

Prefabricated factory size 541 square meters, using the EASYBUILD prefabricated factory structure that can support the installation of a 5-ton crane.

CANNEW Factory

Building size 360 square meters using Ranbuild prefabricated steel building for this medium-sized prefabricated factory.

EASYBUILD ready-made factory building service process

EASYBUILD prefabricated factory building service process The company is equipped with personnel, design team, architects, engineers who are full of With experience and ready to give advice from the first step until the construction of the factory building is completed under the concept of One-Stop Service

1. Prepare the land for the construction of a prefabricated factory. (Time depends on the customer)

For the construction of a prefabricated factory, the first thing to prepare is the land. Before starting any construction work, it is very important to survey the construction site because the size, shape and level of the land all affect the construction of land suitable for the construction of both small and large industrial plants should be similarly shaped land. with the square as much as possible because it will be able to use the usable space more cost-effectively than the long and narrow land

As for the height of the land for the construction of a prefabricated factory, it should be raised to a level that is 30 – 50 centimeters higher than the road surface in order to prevent flooding problems during the rainy season. During the past year, if the land level is lower than required, it should be filled with soil or adjust the soil in the landfill area for the construction of a prefabricated factory. It should be filled about 6 months to 1 year before the construction. collapsed before the start of the construction of the prefabricated factory

2. Design of building plans for the construction of prefabricated factories (2D,3D)

The design of a prefabricated factory must begin by taking the details received from the customer to assemble the prefabricated factory building plan. The prefabricated factory design is a simulation of a prefabricated factory in 2D and 3D images. The basic details of the prefabricated factory building are matched and related to the actual construction of the factory building that must be detailed. That is more than a plan (2D,3D) and the design of a prefabricated factory building plan to suit the size of the land, use of the building primarily, including taking into account the regulations, laws governing the construction of the factory.

3. Make a form for permission to build a factory with the government (customer is the operator)

The use of the site for the construction of the factory must be authorized by the government agencies in that area so that the operation is under building control without causing any negative effects on the society both on the environment and on the other by having to submit a building construction certificate Modification of a building or moving a building (Form Aor. 6) for use in the assembly of an application for establishment of a factory that requires a notification of business operation or permission to operate a factory (Ror. Ror. 1-4) depending on the size of the machine, the amount of horsepower of Machines and the number of workers

which must be carried out in accordance with the procedures and conditions prescribed by the Department of Industrial Works Along with the process of asking for permission to build a factory building, we will provide a service to prepare a design for a construction permit for the customer (at a cost), which will have engineers and architects who have a professional license to sign. But in applying for permission from government agencies, it must be the responsibility of the customer directly.

4. Calculate the cost of the construction of a prefabricated factory building (BOQ)

Calculation of the cost of the construction of a prefabricated factory (BOQ), which stands for Bill of Quantities, which can be translated into Thai as Bill of Materials and Expenses It will show the details of the budget for the construction of the factory building. quantity of material The quality of materials in the construction of all prefabricated factory buildings The customer will receive a BOQ document along with the construction contract that we will prepare for the customer to check and this document can be used to apply for a loan with the bank as well.

5. Submit a factory construction permit form with government agencies in that area. other

After the factory construction permit form has been prepared It comes to the process of applying for a construction permit with that area. By the process of applying for permission, the customer must proceed with the government agency itself. But we will have a sales department to advise in the preparation of various documents. used for permission to construct a factory as well as to the completion of a permit for the construction of a prefabricated factory building

6. Make a contract before starting the construction of a prefabricated factory. (Value of work, payment period, construction period, warranty work)

The prefabricated factory construction contract contains various information. comprising land title deeds Document showing construction quantity (BOQ), construction form, construction permit form, work value, payment period, construction period, warranty work, etc. If the customer wants to apply for a loan with the bank to apply for a loan, this contract document must be provided. Submit a consideration and agree to a contract before starting to proceed with the company in writing before starting the construction of the prefabricated factory.

7. Start the construction of the prefabricated steel factory building.

After signing the contract and paying the first installment and received a permit for the construction of a factory building The next step is Requesting water to use electricity during the construction period can begin the construction of the factory building. During the construction, there will be a team of our engineers to supervise and complete the construction of the prefabricated factory after the final payment will receive a guarantee card.

EASYBUILD Prefabricated factory structure

Prefabricated factory structures EASYBUILD can design prefabricated factory structures with a width of up to 100 meters, without pillars blocking the center of the building, the distance between the side columns is up to 10 meters wide and the wall height from 3 to 30. EASYBUILD standard constructions can be used in a wide variety of applications and can be designed to suit the application for your business. It is also designed to be able to install an overhead crane as well.

Secondary structural parts of prefabricated steel plants EASYBUILD

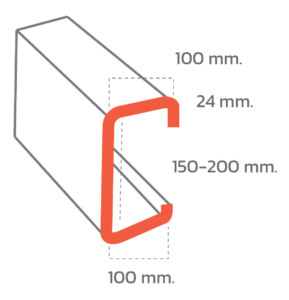

The substructures are made from Cold Formed Members capable of tensile strength up to 450 MPa (65,000 psi) and meet the requirements of ASTM 572 (Grade 65) or JIS G3112 or equivalent.

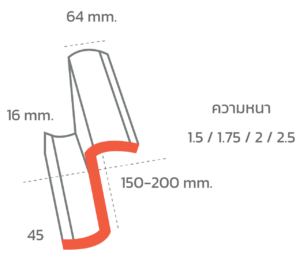

Roof pillow and Z-shape wall anchor ( Z-Purlin / Grit )

The substructures are made from Cold Formed Members capable of tensile strength up to 450MPa (65,000 psi) and meet the requirements of ASTM 572 (Grade 65) or JIS G3112 or equivalent.

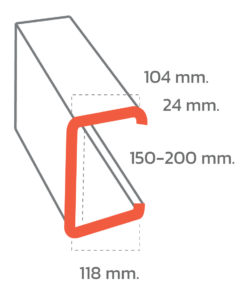

Roof girders (Eave Strut)

The roof girders are 200 mm wide and have fins on two sides that are parallel to The slope of the fit shape The upper fin is 104 mm wide and the lower fin is 118 mm wide. The two ends of the fin are folded up 24 mm.

Design and Engineering

Engineering design works using standard software to design and define building details, both 2D and 3D. The software used is the latest version of a well-known program development company and structural engineer. We have the expertise to use state-of-the-art design systems throughout. Our design and engineering department operates with a fully computerized system at every step of the way to help our customers obtain accurate structural fabrication and cladding systems. The most efficient and cost-effective various software Some of our implements are SketchUp, SAP2000, Tekla Structures, AUTOCAD, RAM Element V8i, Staad Pro and all building constructions are designed according to the latest building guidelines and standards including:

Design Code on all buildings are applied in accordance with:

- AISI (American Iron and Steel Institute) Cold-form Steel Specification, 2001 edition.

- AISC Specification for structural Steel Building -ASD 2005

Design Load on all buildings are applied in accordance with :

- ASCE 7-05 American Society of Civil Engineers